CAE analysis

Evaluation analysis from CAE analysis, proposal of optimum design

Utilizing our design experience in automobile development and railway vehicle development, from initial evaluation to proposal for improvement will be conducted.

Equipment owned by HIVEC

Solver

- Optistruct

- NX Nastran

- Abaqus

- RADIOSS

- LS-DYNA(External equipment)

- MotionSolve

- Inspire

- 3D-TIMON(External equipment)

Pre-post

- HyperMesh

- HyperView

※External equipment: Utilization of Hiroshima Digital Innovation Center (high-speed workstation, supercomputer, various solvers)

Kinds of CAE analysis

Kinds of CAE analysis

- Analysis type linear static analysis

- Linear buckling analysis

- Nonlinear analysis

・Material nonlinearity

・Geometric nonlinearity

・Boundary nonlinearity

- Heat transfer/thermal stress analysis

- Crash analysis

- Eigenvalue analysis

- Frequency response analysis

- Mechanism analysis

- Fluid analysis

- Resin flow analysis

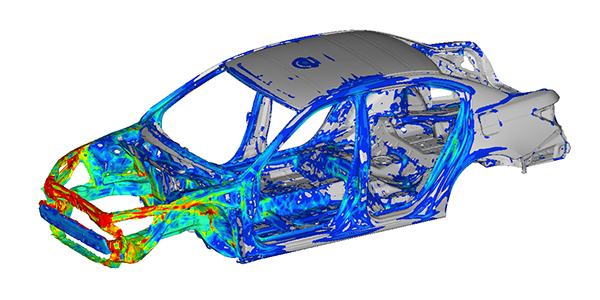

(Case 1) Full-car model 50km/h front collision analysis

RADIOSS: Crash Analysis

(Prediction of car body crush amount)

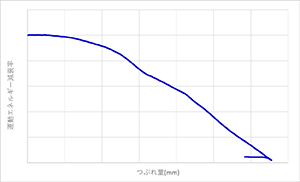

(Prediction of energy absorption characteristics)

Example of a full car model collision analysis

<Created by the U.S. NHTSA and using public data >

Number of elements: 1,919,302 Number of nodes: 1,969,831

<Created by the U.S. NHTSA and using public data >

Number of elements: 1,919,302 Number of nodes: 1,969,831

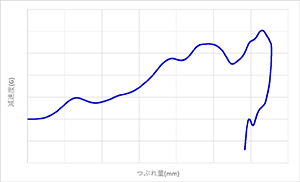

Draw a vehicle deceleration displacement diagram (G-S diagram) from the analysis results and evaluate collision safety performance

(Case 2) Steering vibration analysis

Optistruct: Natural vibration analysis/Frequency response analysis

Example of steering natural vibration analysis with a trimmed body cut model

Number of elements: 411,031 Number of nodes: 443,135

Number of elements: 411,031 Number of nodes: 443,135

Draw the excitation point response function (FRF) from the analysis results and evaluate the idle vibration

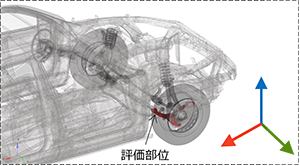

(Case 3) Suspension link mechanism analysis

Motion Solve: Mechanical analysis

An example of link mechanism analysis using a suspension link model

Evaluate whether braking, driving, and turning forces can be properly transmitted to the road surface

(Case 4) Suspension arm strength stiffness analysis

Optistruct: Linear Static Analysis

Stress contour diagram

Stress contour diagram

Example of strength/rigidity evaluation by inputting a static load to a suspension arm

Number of elements: 13,637 Number of nodes: 23,681

Number of elements: 13,637 Number of nodes: 23,681

Draw a deformation diagram and stress distribution diagram from the analysis results and evaluate the strength

(Case 5) Steering boot large deformation analysis

Abaqus: Nonlinear analysis

Example of geometric nonlinear analysis on steering boot model

Evaluate the stress/interference when climbing over a protrusion by reproducing the compression expansion and contraction of the boot.

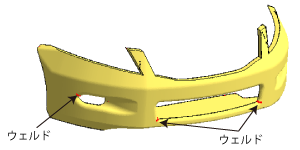

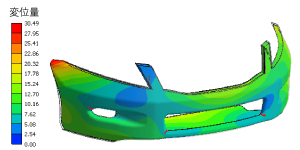

(Case 6) Resin flow analysis of automobile interior and exterior parts

3D-TIMON: Resin flow analysis

Example of resin flow analysis performed on a bumper mold model

Number of elements: 309,162 Number of nodes: 103,146

Number of elements: 309,162 Number of nodes: 103,146

Evaluate weld and warp deformation with molding conditions as parameters

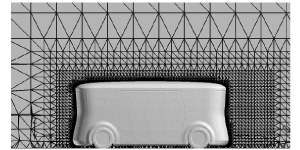

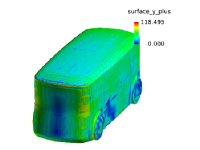

(Case 7) Analysis of gas flow around a vehicle

AcuSolve: Flow analysis

Example of flow analysis performed on the exterior model of a community bus

Number of elements: 20,396,652 Number of nodes: 3,735,379

Number of elements: 20,396,652 Number of nodes: 3,735,379

Calculate the gas flow around the vehicle and evaluate the flow velocity/static pressure/Cd value

(Case 8) Heat transfer and thermal stress analysis of a vessel

ABAQUS: Unsteady heat transfer/thermal stress analysis

Deformation magnification: 5 times

Example of heat transfer and thermal stress analysis using a model in which the container is heated from the bottom

Number of elements: 316825 Number of nodes: 250817

Number of elements: 316825 Number of nodes: 250817

Evaluate thermal stress during heating transition by reproducing the thermal expansion of the time history during heating